-

avm@avmsystech.com -

+91-9850036218, +91-9850036217, +91-8484811438

Products

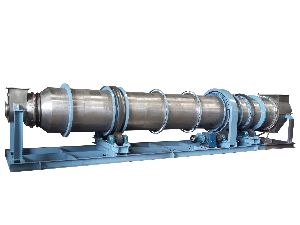

New AVM Systech Pvt. Ltd. is one of the leading company specialized in manufacturing and export of Industrial Dryers, Coolers, Calciners, Allied Equipments and Systems.

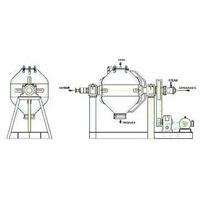

Vacuum Dryer are widely used in the Industry for drying of variety of products.

Vacuum Dryer is batch dryer ideal for drying of heat sensitive products, drying of products in solvents (for subsequent solvent recovery), drying requirements necessitating achievement of very low moisture or low oxygen drying environment to minimize oxidation or for explosion prone products.

Read More...

Vacuum Dryer is batch dryer ideal for drying of heat sensitive products, drying of products in solvents (for subsequent solvent recovery), drying requirements necessitating achievement of very low moisture or low oxygen drying environment to minimize oxidation or for explosion prone products.

Other Products